Nano Dimension

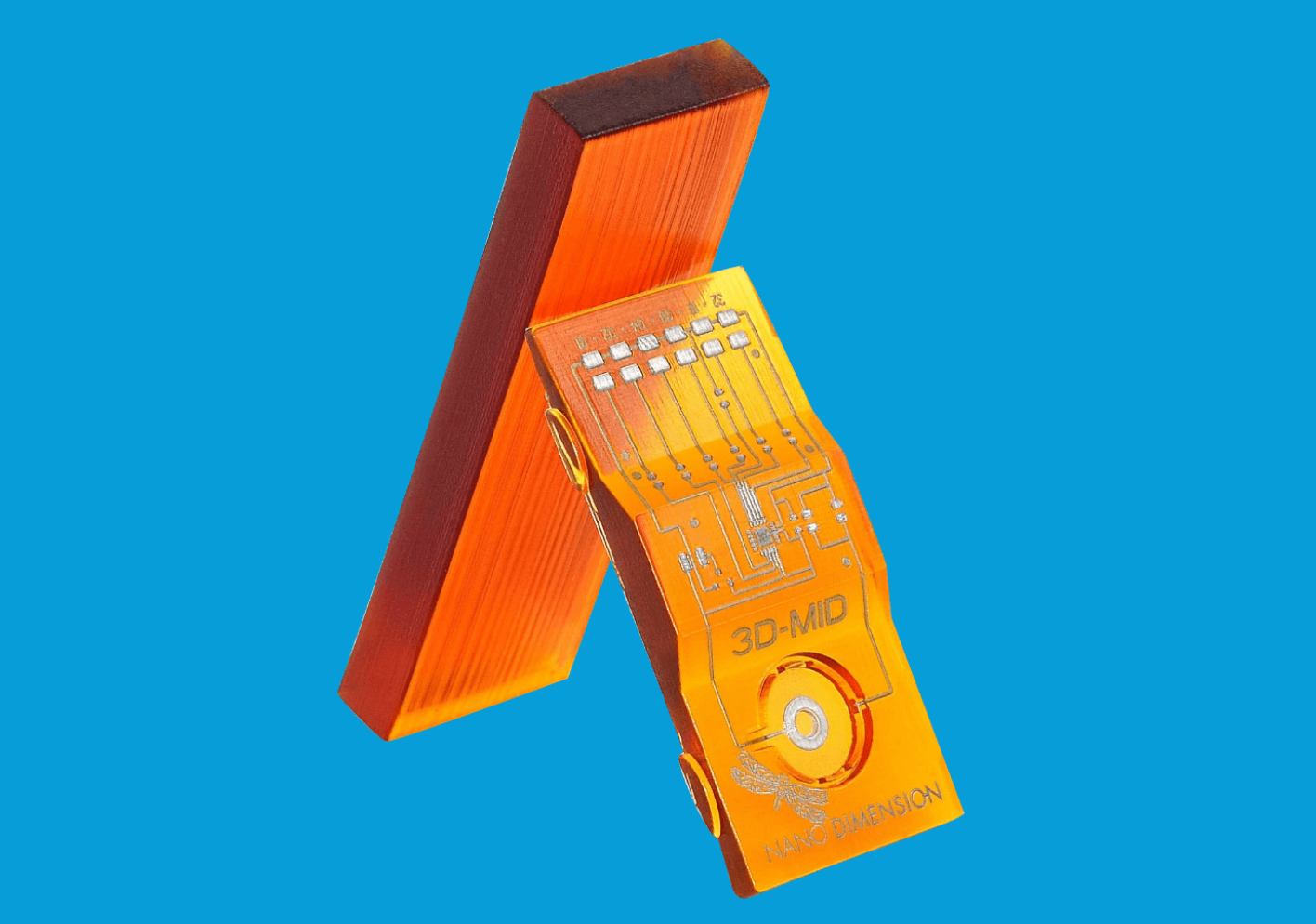

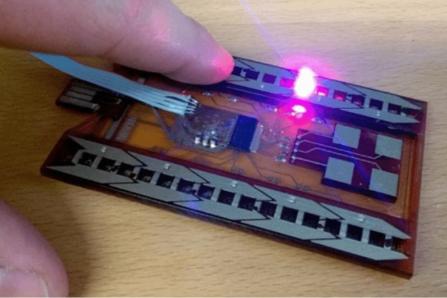

Additive Manufacturing Electronics (AME) technologie is een unieke techniek om Hi-PEDs® - High-Performance Electronic Devices, laag per laag, vanaf nul te printen. Hi-PED's® zijn elektronische printplaten met complexe geometrieën die niet kunnen worden geproduceerd in het traditionele printplatenproductieproces. De technologie injecteert gelijktijdig diëlektrische polymeerinkt en geleidende zilverinkt uit een speciale printer, DRAGONFLY IV genaamd.

Het past zich snel aan de vereiste grootte van de pads en hun afstanden tussen de lagen aan, waardoor de proof of concept (PoC) productietijd wordt verkort.

Tijd

Verkort de cyclustijden voor ontwikkeling. Maakt prototyping ter plaatse mogelijk in enkele uren in plaats van weken, zelfs voor complexe ontwerpen.

Cost

Elimineert de noodzaak van grote orderminima. Biedt de mogelijkheid om ontwerpfouten in een vroeg ontwikkelingsstadium te ontdekken met agile rapid.

24/7

Maakt lange, ononderbroken runs rond de klok mogelijk, met minimale supervisie, wat een verbetering van de totale doorvoer van het systeem mogelijk maakt.

Automatisering

Automatisch mechanisme en algoritmen voor printkopbeheer, waardoor ononderbroken printen mogelijk is met minimale printopdrachtinstelling en preventief onderhoud.

Complexe Geometrie

Maakt uitgebreid, niet-conform ontwerp mogelijk, dat niet wordt beperkt door 2D-vlakke beperkingen, voor een betere minitirisatie en een beter gebruik van de beschikbare ruimte.

Consolidatie van componenten

Additive Manufacturing met meerdere materialen maakt functionele, compacte, dichtere, niet-vlakke elektronica-onderdelen mogelijk.

Vertrouwelijk

Maakt het mogelijk om gevoelige IP tijdens de ontwikkeling intern te houden. Wegnemen van zorgen over IP-diefstal, inbreuk, gegevensbeveiliging en meer.

Duurzaam

Beperkt de impact op het milieu door een geoptimaliseerd ontwerp, formaat en gewicht. Vermindert afval met additieve productiemogelijkheden.

> 15 jaar ervaring

Ervaring, kennis en klanttevredenheid zijn dé bouwstenen van ons bedrijf

Distributeur voor BENELUX

Uw lokale Benelux-partner met service-activiteiten en kantoren in de hele regio

Ga voor de beste deal

Financieringsmogelijkheden voor elke gelegenheid (renting, leasing, trade-in)

Printers binnen deze technologie

DRAGONFLY IV

Met de DragonFly Lights-out Digital Manufacturing (IV) 2.0 printer kunnen nu 24/7 functionele circuits en apparaten worden geproduceerd met weinig tot geen tussenkomst van de operator. Het DRAGONFLY IV precisie additief productiesysteem, een product van Nano Dimension, is het meest geavanceerde platform voor rapid prototyping en low-volume manufacturing van hoge resolutie, multilayered 3D-geprinte elektronica.

Het DRAGONFLY IV Lights-Out Digital Manufacturing-systeem is het enige complete additieve fabricageplatform in de industrie voor het 24 uur per dag 3D-printen van elektronische schakelingen. Dit precieze additieve fabricageplatform integreert op unieke wijze een uiterst nauwkeurige inkjet depositieprinter met speciale nano-inkten en geoptimaliseerde 3D-software om elektronische circuits zoals antennes, condensatoren en sensoren te printen.

Met de DRAGONFLY IV kunnen ontwerpers snel van concept en ontwerpvalidatie naar productie van elektronische precisiecomponenten gaan, terwijl het hele proces veilig in eigen huis wordt gehouden. Bedrijven kunnen nu de vraag naar middelen voor prototyping en productie in kleine series verminderen en de totale bedrijfskosten verlagen in vergelijking met traditionele productiemethoden.

Printproces:

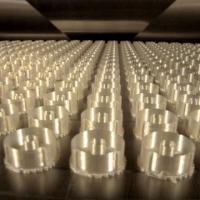

Simultaneous multi-material additive manufacturing is een revolutionaire benadering die helpt de elektronica van morgen te herdefiniëren voor attributen zoals dichtheid, grootte en flexibiliteit. De DRAGONFLY IV is uitgerust met twee printkoppen, één voor geleidende nano-zilverinkt en de andere voor diëlektrische polymeerinkt. Dankzij deze opstelling kan de DRAGONFLY IV met beide geavanceerde inkten gelijktijdig printen in één enkele printopdracht.

Het DRAGONFLY IV inkjet depositie systeem zet nieuwe precisiestandaarden voor 3D-geprinte elektronica, waardoor het ideaal is voor industrieën met de meest veeleisende ontwerp- en kwaliteitseisen, zoals lucht- en ruimtevaart, automobielindustrie, telecommunicatie, gezondheidszorg en meer.

Stel je volgende scenario's voor:

- Vrij innoveren zonder beperkingen van het traditionele productieproces.

- Het printen van afzonderlijke delen van een circuitontwerp voor testen tijdens de productie.

- Het maken van vias en doorvoeropeningen zonder dat boren of beplating nodig is.

- Het printen van elektronische circuits in eigen huis in slechts enkele uren.

- Innoveren en tegelijkertijd ruimte, gewicht en kosten besparen met ontwerpen die complexe geometrieën en nieuwe functies bevatten.

- Gestroomlijnde workflows en eenvoudige bediening

- Lange ononderbroken 3D print runs met minimale supervisie voor een verhoogde uptime.

Downloads

> 15 jaar ervaring

Ervaring, kennis en klanttevredenheid zijn dé bouwstenen van ons bedrijf

Distributeur voor BENELUX

Uw lokale Benelux-partner met service-activiteiten en kantoren in de hele regio

Ga voor de beste deal

Financieringsmogelijkheden voor elke gelegenheid (renting, leasing, trade-in)