3D printing of production equipment

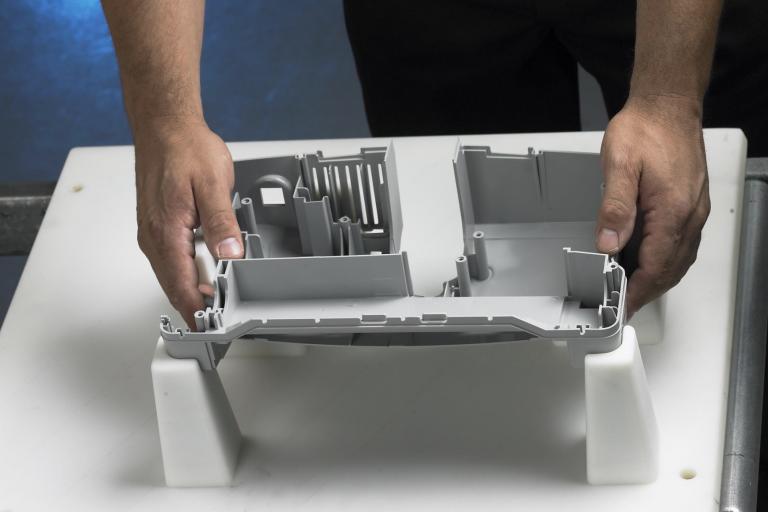

Jigs & Fixtures

Producing custom molds and fixtures can be done easily, quickly and cost-effectively on site with 3D printing

Why use 3D printing technology for Jigs & Fixtures?

To maintain quality, efficiency and safety, companies rely on custom jigs and fixtures to position, protect,... Parts at all stages of the production process.

3D printing can significantly improve the production of these tools and resources, removing cost and design barriers.

- FDM 3D printing technology builds plastic parts, layer by layer, directly from CAD files. This simplifies the entire process, is cost effective and less time consuming

- Evaluate and make immediate improvements to the model

- With FDM, tools can be created for optimal performance and ergonomics

- Molds and fixtures, made from durable thermoplastics, are strong, lightweight and resistant to harsh (production) environments

- Biocompatible materials are ideal for the medical industry

- The multi-materials of PolyJet technology allow to create customized molds and fixtures, adapted to everyone's needs

Case Studies

Over 20 years of experience

Experience, expertise, and customer satisfaction are the cornerstones of our company.

Authorized distributor

Your AM partner in the Benelux, France, and the Nordics, with service operations and local offices in each region.

Go for the best deal

We offer a range of financing options to suit every use case, including renting, leasing, and trade-in solutions.