Robot Tooling

Robot Tooling

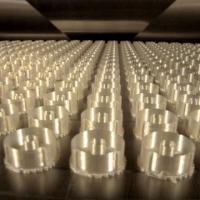

Transcend the limitations of traditional manufacturing with 3D printed end of arm tools (EOAT).

Why use 3D printing for robot grippers?

Robots are used to perform a variety of tasks with exceptional speed and precision.

3D printing end-of-arm tooling components saves time and costs while producing lighter parts that offer better performance and durability.

Make it faster |

Lighten it up |

Make it more efficient |

| Get more out of your production with lightning-fast EOAT development via 3D printing. No more waiting times for outsourcing or machining – print your gripper overnight and deploy it immediately the next day. | Create lighter end-of-arm tools that use less energy. With FDM technology you can print strong but light parts, from technical ABS to high-performance thermoplastics. | Print EOATs on demand and avoid the material costs and long delivery times of traditional production. Customization or a design adjustment? Just adjust your CAD model and print a new part – it's that simple. |

Case Studies

3D printers for robot tooling

Contact SEIDO for more information

Over 20 years of experience

Experience, expertise, and customer satisfaction are the cornerstones of our company.

Authorized distributor

Your AM partner in the Benelux, France, and the Nordics, with service operations and local offices in each region.

Go for the best deal

We offer a range of financing options to suit every use case, including renting, leasing, and trade-in solutions.