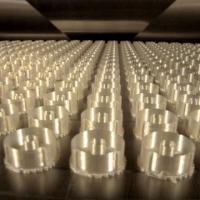

Production & end-use parts

Production & end-use parts

in series and suitable for end use

3D printing production parts when you need them, without the high costs and long lead times of traditional CNC and injection molding technologies.

When is which technology the best choice? Read all about it in this exclusive e-book.

Why 3D printing?

- Faster and cheaper than with traditional techniques – no expensive moulds, tooling or long lead times.

- On-demand production in-house – reduce inventory costs and accelerate product development.

- Reliable quality with Stratasys technology – repeatable, accurate and consistent.

- Flexibility in design – Complex geometries and internal structures possible at no extra cost

- On-demand production – Produce only what you need, when you need it

- Cost-saving for small series – Ideal for low volumes where injection molding is not cost-effective

- Fast iteration – Easy adjustment and reprinting of designs

- Local production possible – Less dependent on global supply chains

3D printing of ESD-safe parts

Sensitive electronics are particularly vulnerable to electrostatic discharge (ESD), which can lead to defective components, expensive repairs and recalls.

But what if you could produce ESD-safe tools and components with injection molding quality — at a fraction of the cost and lead time?

Webinar: ESD-safe Tools & Products

During this webinar, experts from... Stratasys and Henkel Loctite 3D their insights into how 3D printing enables the production of ESD-safe end-use products – in small and medium-sized series. |

|

Case study: Spectra Group

|

Spectra Group , a specialist in advanced communications solutions for defense and security, has invested in a Stratasys Origin 3D printer. Thanks to this technology, they can now end-use parts in series manufacturing with a wide range of high-quality materials. Read more in the case study below. |

3D Printers for production and end-use parts

DLP technology

The quality and finish of injection molding, with stunning accuracy and high-quality materials

SAF technology

The H350 powder bed technology is the most cost-efficient way to produce parts in series.

FDM technology

FDM printing is the on-demand solution for the cost-efficient production of small series and design iterations.

Injection molding vs Additive manufacturing

For series of up to several hundred thousand pieces, 3D printing offers many advantages over injection molding. It is a tool-free technology – no investment in molds or dies is required – allowing you to produce flexibly and on-demand without high start-up costs.

Read more about the benefits of both technologies in this exclusive e-book:

Download the ebook

Save time and money

- Traditional production is slow and expensive

- 3D printing is fast and affordable for prototypes and small series

- Short runs reduce costs and increase profits

- Faster prototyping = better products and shorter time to launch

Create complex shapes

- Complex shapes and geometries

- A complex part can be printed in days instead of weeks

- No tooling or molds required, which saves time and costs

- Suitable for both small and large production series

Large choice of materials

- Suitable for electronics, medical and automotive parts, among others

- Strong, durable and heat-resistant top materials such as Nylon 12 and ULTEM 9085

- Complies with strict FST (Fire, smoke, toxicity) standards, ideal for aviation applications such as ECS air ducts

Local and on-demand

- Less dependent on global supply chains

- Reduce inventory costs

- Accelerate the development cycle

“We expect that many of our high-accuracy, low-volume products will now be 3D printed instead of injected.”

Over 20 years of experience

Experience, expertise, and customer satisfaction are the cornerstones of our company.

Authorized distributor

Your AM partner in the Benelux, France, and the Nordics, with service operations and local offices in each region.

Go for the best deal

We offer a range of financing options to suit every use case, including renting, leasing, and trade-in solutions.