Stratasys F170

From prototypes to robust tooling

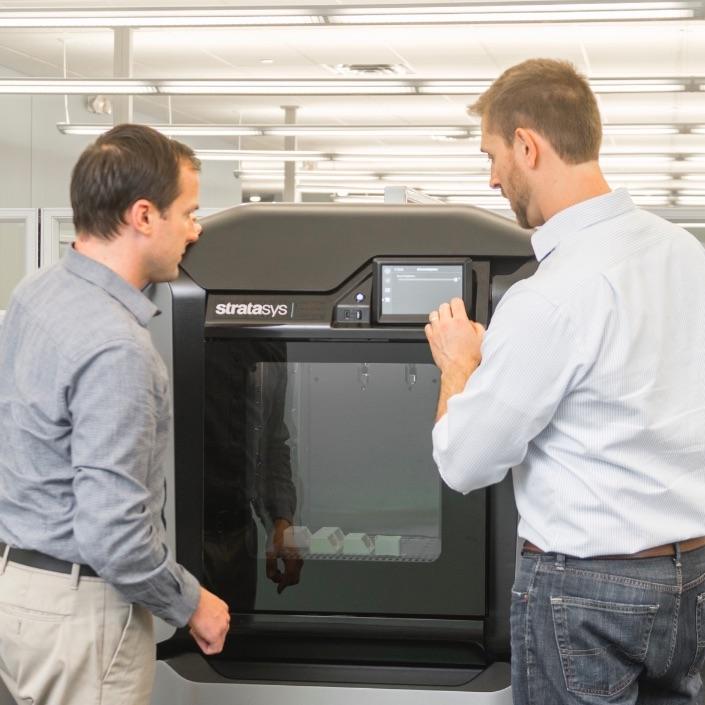

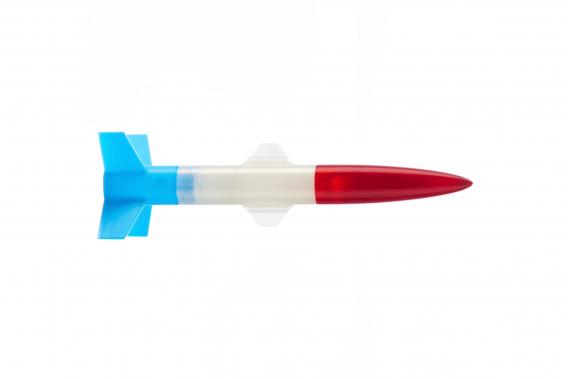

Design engineers know how to convert their designs into a physical prototype using 3D printing. However, Stratasys has not only developed the F170 for product designers, but also for the final makers. With this compact 3D printer, they can easily print gauges and clamping devices for production. In high quality, straight out of the box! There are several materials available for the F170 3D printer. These range from PLA, ASA and standard ABS flexible TPU and carbon fiber filled ABS.

The latter filament has been specially developed for 3D printing of production tools that are subject to heavy loads. The optimal coordination between 3D printer and material and the integration into the GrabCAD Print software from Stratasys makes 3D printing easy with any printer from the F123 series. The accuracy of the 3D printed workpieces is at a high level, even for those who have no experience with 3D printing.

| Construction volume: | 254 x 254 x 254mm |

| Layer thicknesses: | 0.127 / 0.178 / 0.254 / 0.330mm |

| Materials: | 5 different materials |

* Patented heated building chamber

* Water soluble support material

Reliable results

High accuracy and repeatability with engineering grade materials

Streamlined workflow

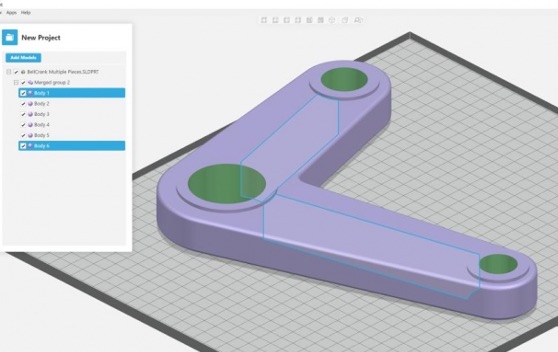

Go directly from CAD file formats to 3D printing with GrabCAD Print software

User-friendly

Quick and easy material changes - maximize your team's productivity

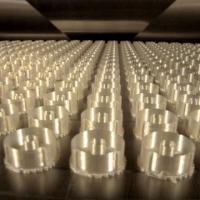

Jigs & fixtures

Create simple molds & tooling in various thermoplastics.