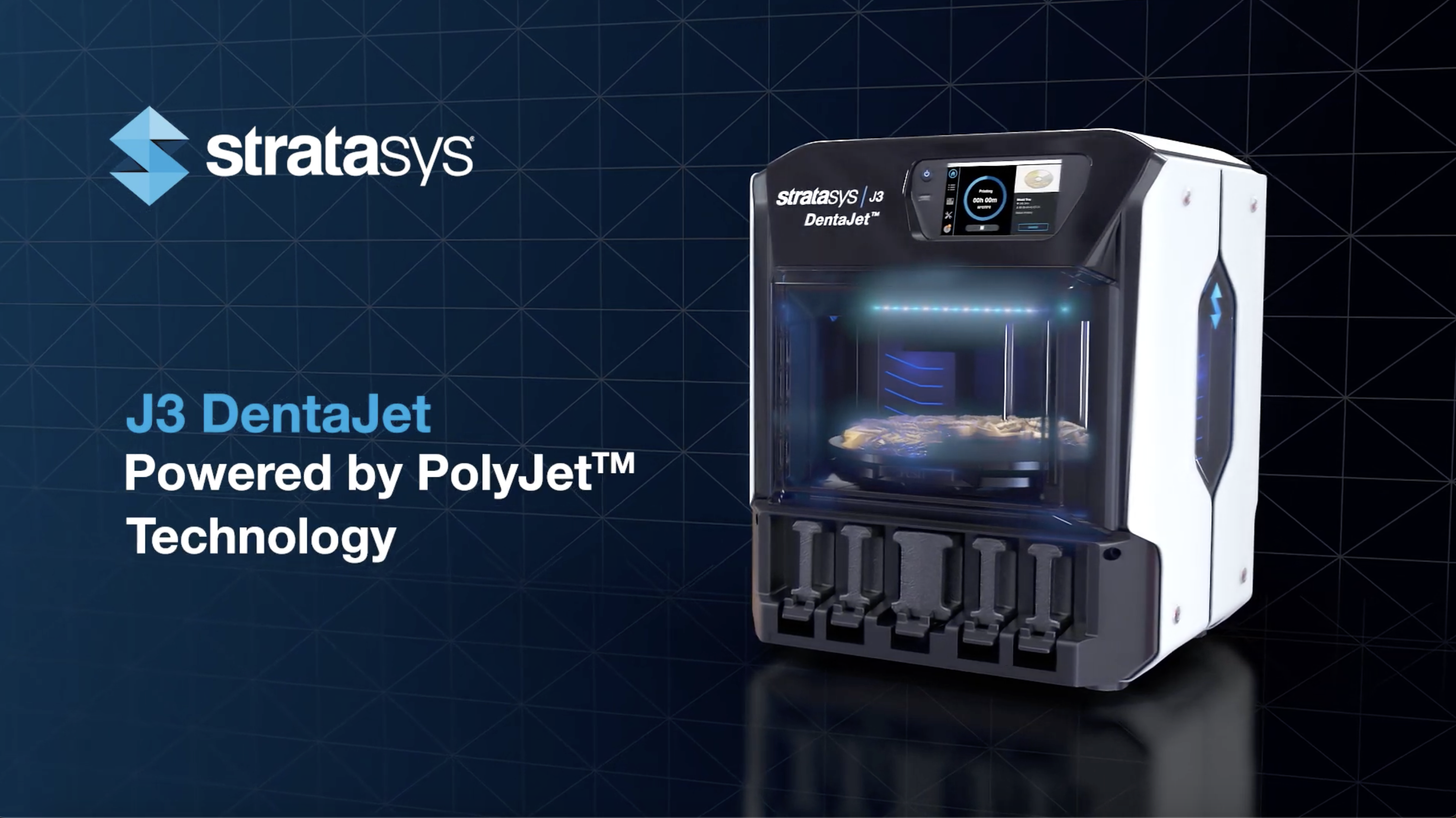

J3 DentaJet

3D printing has become indispensable in the dental laboratory. Implant models, frames, molds for casting crowns and bridges: with 3D printing, every dental laboratory shortens the turnaround time.

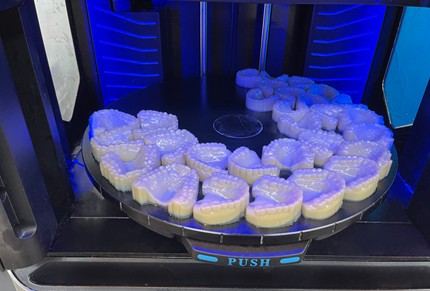

The J3 DentaJet is the user-friendly office printer for the dental practice, which combines up to 3 different materials in one build job. This also allows smaller labs to 3D print efficiently.

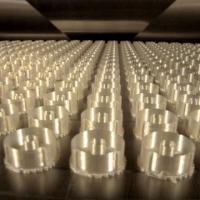

Stratasys' unique support material saves significant time when releasing the models from the platform.

Stratasys' special GrabCad software simplifies the operation of the J3 DentaJet, even without 3D printing experience. The software automatically ensures the correct positioning on the construction platform so that a maximum number of products are printed at once, which ensures lower costs per product.

| Maximum print: | 140 x 200 x 190mm |

| *table area: | 1 174 cm2 |

| Layer thickness: | 18 microns |

Biocompatible materials

Rubber-like materials

Rigid materials (full color)

Implantology

Accurate implant printing: rigid models, transparent guides and soft gingival masks - all on one biocompatible tray - in a single print job

Orthodontics

Shorten delivery times and produce more orthodontic appliances in a short time.

Indirect bonding plates

Simplify the production of acrylic orthodontic appliances with Separator Digital Material that coats the models for easy removal of acrylic and wax.

Crowns and bridges

Produce high-volume models in high-resolution materials with realistic color matching.