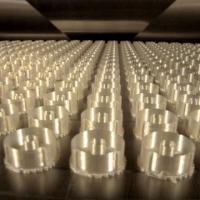

Better injection molding thanks to 3D printed mold inserts

3D printing of injection molds with integrated and optimized cooling channels is one of the oldest applications of 3D metal printing. Yet you don't come across it often. Xact Metal will work with partners to breathe new life into this application. SEIDO Systems, the Benelux dealer of the American printer manufacturer, will present this solution for better injection molding in September at the Plastics Fair.

Corrosion: according to Juan Mario Gomez, CEO of Xact Metal, this is one of the main reasons why 3D printing of inserts for injection molds has never achieved widespread success. The American printer manufacturer solves this by collaborating with Uddeholm. The Swedish group supplies Corrax metal powder for the Xact Metal 3D metal printer, which is supplied in the Benelux by Seido Systems .

Corrax has good anti-corrosion properties

Corrax is a widely used cobalt-free tool steel, which has excellent anti-corrosion properties. Mold makers use it for milling and arcing injection molds. Xact Metal and Uddeholm will now develop the correct parameter settings for the 3D metal printers, with Uddeholm contributing the material expertise. According to Gomez, Corrax powder prints just as well and beautifully as stainless steel powder. The big advantage is that the cooling channels do not show corrosion over time during the use of the mold inserts. “Regular tool steel corrodes over time. We solve that disadvantage with this.”

Post-processing for a mirror-smooth surface

The second bottleneck is the surface finish of the inserts for injection molds. Plain tool steel or maraging steel (MS1, M300) can only achieve an A2 finish after secondary post-processing. However, parts printed with Corrax can be finished by hand up to A1 (mirror surface) after heat treatment. This opens up more possibilities in the injection molding industry for 3D printing of lens molds and other optical molds. The conformal cooling channels, which can be closer to the mold wall, reduce the external pressure encountered when molding clear polycarbonate for optical parts.

Oqton automatically places cooling channels in CAD model

The second partner that Xact Metal brings in is software developer Oqton. With 3Dxpert, Oqton's software, optimized cooling channels can be automatically installed in a mold, thereby shortening the cycle time of plastic injection molding or improving the surface quality of plastic parts. While it is still advisable to use software such as Moldex3D for cooling analyzes and simulations to demonstrate the optimal impact on cycle times, Oqton's 3Dxpert software reduces the design effort. This software helps to seamlessly integrate additive manufacturing into the workflow of mold makers. Xact Metal also collaborates with Moldex3D, software for optimizing conformal cooling and making flow analyzes of injection molding.

Industry requires a total solution

Juan Mario Gomez believes that this approach can convince the injection molding industry to use additive manufacturing more often. “We have to offer a total solution. Many mold makers think that the costs of the whole thing are too high.” Xact Metal has therefore started a campaign in the US under the slogan “Breaking the mold, the Xact Solution to better tooling”. Injection molding companies are also involved who clearly indicate that they benefit from this solution.

Conformal cooling molds improves casting of optical components

Plastics fair

In the Benelux, the injection molding and mold industry can become acquainted with the 3D metal printing solution for inserts at the Plastics Fair in September. SEIDO Systems exhibits during the fair at the AM for Plastics Area – a special 3D printing square aimed at the plastics industry – and will, in addition to Stratasys' 3D printing technology – for plastics – also demonstrate Xact Metal's mold technology. The Plastics fair will take place on September 18 and 19 in the Brabanthallen in 's Hertogenbosch.